A large-tonnage multi-rope crane experienced a noticeable tilt of the hook sheave pin. During operation, the hook no longer remained level; instead, it tilted upward or downward on one side when hoisting or lowering. This article analyzes the causes of this issue and proposes practical solutions for reference.

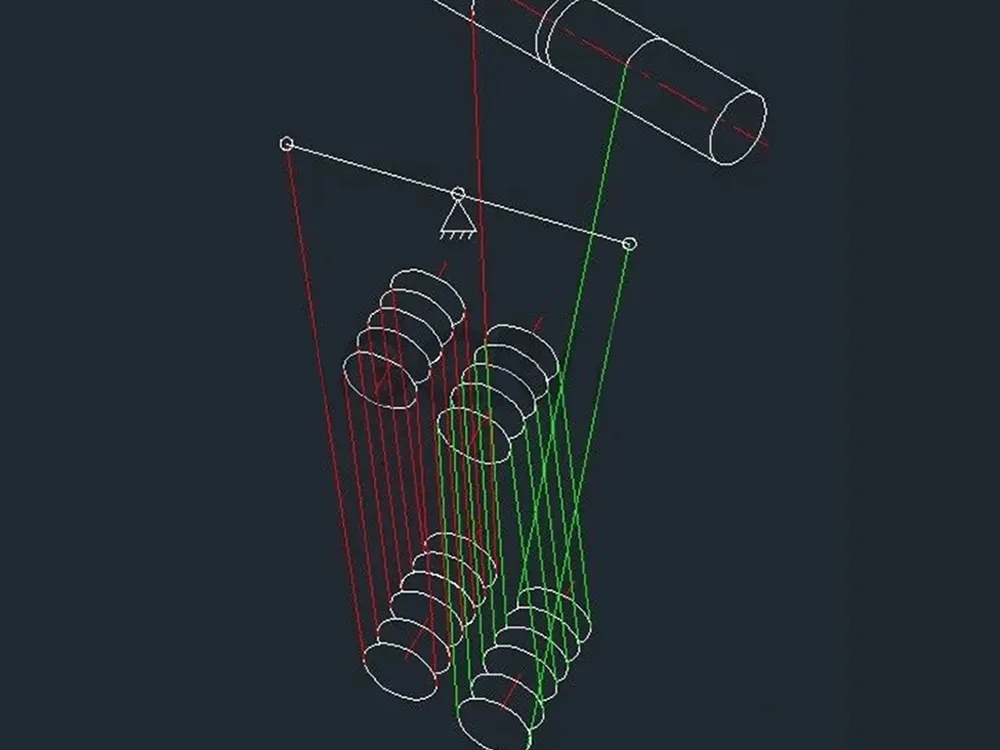

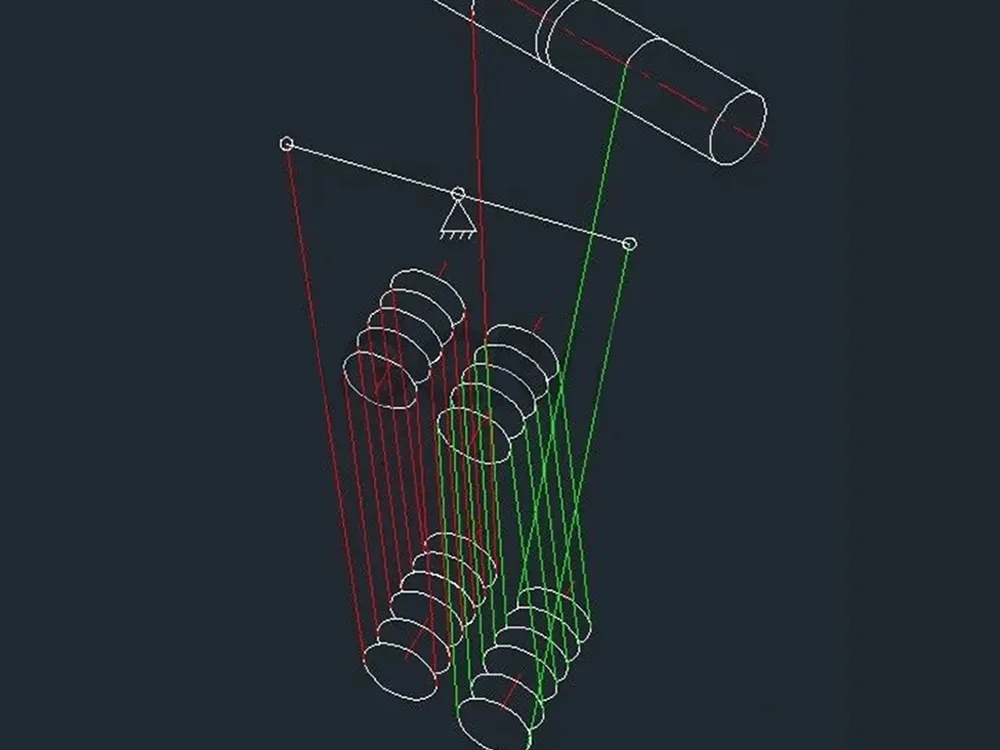

Based on the hook arrangement shown in the figure, the reeving diagram can be inferred as follows:

Causes of Hook Misalignment

Causes of Hook Misalignment

Essentially, hook misalignment occurs due to uneven tension or asynchronous movement of wire ropes on the sheaves. For multi-part reeving systems, the level of misalignment shown in the figure is relatively common.

During the winding and unwinding of the drum, friction exists between the wire rope, sheaves, and sheave bearings. As a result, the wire rope closest to the drum moves first, followed by the second and third rows of sheaves, and finally the rope segment near the dead end.

As the reeving ratio increases, the movement on the drum side becomes significantly greater than the movement on the dead-end side. At this stage, the hook sheave pin tends to tilt. Once winding or unwinding continues and all sheaves begin rotating, the rope tension gradually becomes balanced. Due to the self-weight of the hook and the load, the sheave pin eventually returns toward a horizontal position.

Solutions to Hook Misalignment

1. Double-rope drum or four-rope single-reeving drum

In a single-drum, double-rope reeving system with a high reeving ratio, the sheave near the dead end engages later, causing tension differences. Eliminating the dead-end termination and ensuring both ropes wind and unwind simultaneously can significantly stabilize the sheave pin.

2. Replace the wire ropes and bearings

Use wire ropes with better flexibility and bearings with lower friction resistance, and ensure proper lubrication of both the rope and bearings.

3. Increase the hook weight

A heavier hook provides a greater stabilizing moment, reducing its tendency to tilt.

Each method has its own advantages and limitations and may incur additional costs. In practice, slight misalignment is normal and acceptable as long as it does not affect operational safety.

Note: If the reeving system does not include an equalizer beam as shown in the diagram, the two ropes may carry uneven loads.

Conclusion

Crane hook misalignment is mainly caused by uneven rope tension and asynchronous rope movement. By optimizing the reeving system, selecting suitable components, and increasing hook weight, the issue can be effectively mitigated. In real-world applications, the most appropriate solution should be chosen based on equipment conditions and with safety as the top priority.